The history of Larry and his recent engine rebuild

Larry the Adler is a 1910 veteran car pictured above, adopting his name after the famous American harmonica player Larry Adler. In Larry’s later career, he played with the likes of Sting, Elton John and Kate Bush. Read on to learn story the of Larry the car, not the musician!

Manufacturer: Adler

Date: 1910

Engine: 4 cylinder 1750cc 12hp

Gearbox: 3 speed.

Brakes: Rear-wheel brakes with expanding shoes, coupled with transmission brake.

Larry Adler, American Musician

Old sketch of an Adler Car

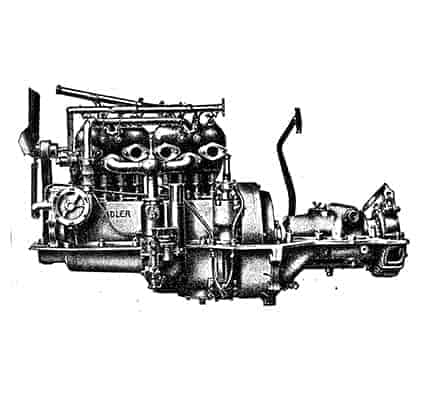

Old sketch of Adler engine

Larry Adler’s History

The engine and chassis were imported from Frankfurt, Germany where it was manufactured in 1910 by Adler – a German bicycle and automobile manufacturing company that survived from 1900 to 1957. Adler means eagle in German. Now in England, Larry sat feeling sorry for himself in the corner of coach-builder Morgan and Company’s workshop in Leighton Buzzard. He sat there for a few years until a local dentist, Dr Bailey King commissioned a 2 seater body to be placed on the naked Larry – the body that you see on the car to this day! The doctor was inordinately large and thus had the seat moved 3” back to give adequate relief around the steering wheel.

Larry was then passed to a local garage where he was used as a taxi throughout the First World War. He then rested for 35 years in a shed which overhung the Canal, waiting for the next owner. After this slumber, the car passed through a few hands before eventually finding its way to the current owner, who purchased Larry in October 1970! Over the last 50 years, Larry has been thoroughly enjoyed, travelling around Europe and competing in several Veteran car club events.

October 1965

1971

1971

“Thank you for carrying out the engine rebuild on my 1910 Adler. Although I am still running in the engine, it is clear that it has never run better during my forty year plus ownership. Most impressive is that it now no longer overheats, something from which it has suffered for decades.”

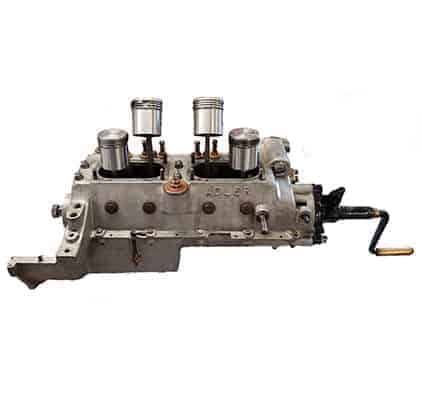

Larry Adler’s engine rebuild

While stripping the engine, it was imperative that we carefully measured, marked and recorded the process to ensure it was correctly reassembled and also so that we could be sure to replace components that were unserviceable. The crankshaft splits into 5 sections, and each cam lobe individually clamped to the camshaft – a very interesting design that made it all the more daunting to strip! As we stripped the engine each component was closely examined for wear, and main components for example, these crankshaft sections, were also crack tested to ensure they were safe to reuse. The valve timing was fastidiously measured before removing the timing gears. With the measurements we had taken, we were able to manufacture a new set of gears to last another 110 years! We bored and honed the cylinders, replaced the pistons and piston rings, and machined new little end bushes for the con rods. The valve train was also replaced, machining new valve seats into the mono-block to ensure a proper seal and correct fitment. Everything was thoroughly cleaned prior to assembly.

“I can now look forward to happy times spent at the wheel of ‘Larry’ and the occasional Veteran Car Club Rally.”